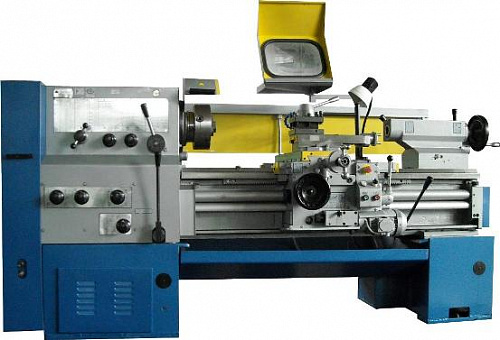

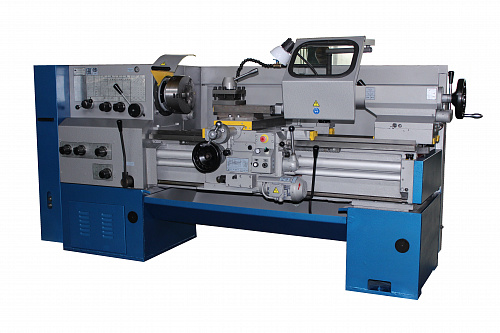

The machine is designed to perform a wide variety of turning operations, as well as for cutting metric, inch, modular, and pitch threads.

The machine can be used in various industries for all kinds of operations for processing different materials. In this regard, the maintenance of the machine should be carried out considering the specifics of its operation.

The machine is equipped with an apron with a built-in high-speed motor and a feed box that provides the ability to cut threads of 11 and 19 threads per inch without changing the gears in the engine gearbox.

Depending on the modification of the machine, the following alphanumeric indices are added to the basic designation:

"S" - when equipping the machine with a drilling and milling fixture;

"V" - machine with the largest diameter of the workpiece to be installed above the bedplate 630 mm, the workpiece to be processed above the 420 mm caliper;

"A" - machine with a modified profile of the bedplate guides;

"G" - machine with a recess in the bedplate;

"D" - diameter of the cylindrical hole in the 70mm spindle;

"K" - machine with a closed rear zone;

"L" - machine with a limb division value of the transverse movement of 0.02 mm;

"M" - machine with a mechanized drive of the caliper group;/

Machine with various digital indication devices (DRO) and linear movements transducers: "C1" ("Fagor"), "C2" ("SKB IS"), "C3" ("SINO"), "C4" ("Optimum"), "C5" (“Ditron”) - with photoelectric linear movements converters; "C6" ("Ditron"), "C7" ("SKB IS") - with magnetic linear movements transducers, etc.

RU

RU EN

EN BY

BY