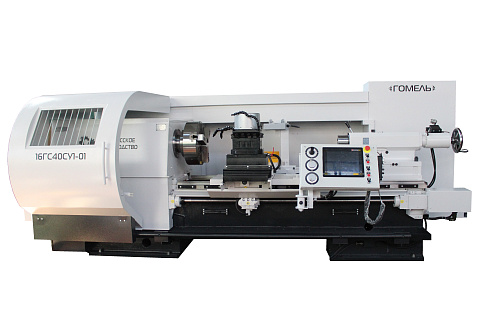

The machine is designed for turning in a semi-automatic cycle in the chuck or centers of parts with straight, stepped and curved profiles in small-batch and serial production.

The machine has an operational control system designed to reduce the qualification requirements of the machine operator while providing CNC machine-level functionality. Easy-to-understand menu-driven operation from the large touch screen. All required part processing modes are conveniently grouped in a simple and intuitive operator dialog.

The range of spindle speed and feed control makes it possible to process products from both conventional ferrous and non-ferrous metals, as well as alloy steels.

The machine can be used in various industries in all kinds of operations to process different materials with small repetitive batches of parts.

The machine is equipped with a Mitsubishi CNC system, the machine is manufactured with a center-to-center distance of 1500 mm.The machine is equipped with a conveyor belt for chip removal, air conditioning, hydraulic clamping of the workpiece in the chuck, hydraulic clamping of the tailstock pinole, hydraulic switching of the spindle gear blocks, automatic lubrication of longitudinal and transverse guides.

RU

RU EN

EN BY

BY