The eight-position automatic head is used for automatic indexing of cutting and auxiliary tools installed in a tool disk with a horizontal axis of rotation. The eight-position automatic head is designed to equip lathes with various numerical control systems.

The head with a horizontal axis of rotation is designed for installation, fastening and automatic indexing of cutting and auxiliary tools.

The heads are equipment nodes for lathes with various numerical control systems and are used for chuck-center work under UHL4 operating conditions according to GOST 15150.

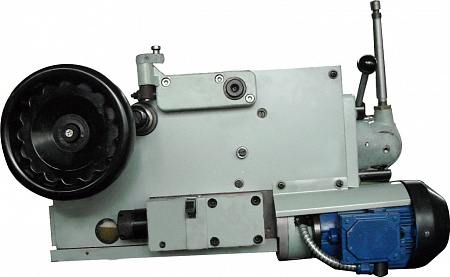

The apron is designed to convert the rotational movement of the lead screw and the drive shaft into the longitudinal movement of the carriage and the transverse movement of the caliper, as well as for manual control of these movements during the operation of the machine (turning on and off the working and accelerated movements of the carriage and caliper, reversing movements, etc.).

The feed box is designed to change the gear ratio when transmitting rotation from the input shaft of the feed box to the lead screw or lead shaft of screw-cutting lathes. A general view of the feed box is shown in Fig. 1.

With the help of the feed box, the relative movements of the cutting tool and the workpiece necessary for efficient and productive work are carried out, ensuring that parts of the desired configuration are obtained with the required accuracy and surface finish.

Back rest model 086.23 (097.23), fixed rest model 086.26 (097.26) are designed for machining parts on lathes mod. GS526 with the index "V" and its modifications with a distance from the horizontal plane of the bedplate to the axis of the centers of 250 mm (320 mm).

RU

RU EN

EN BY

BY