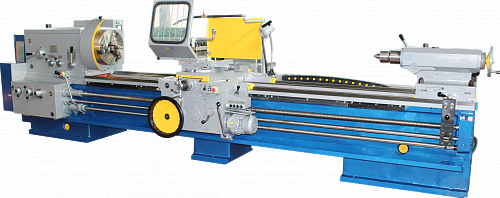

The machine is designed to perform a wide variety of turning operations, as well as for cutting metric, inch, modular, and pitch threads.

The machine can be used in various industries for all kinds of operations for processing different materials. In this regard, the maintenance of the machine should be carried out considering the specifics of its operation.

Adjustment of the machine caliper for the processing of long cones is carried out a combination of mechanical movements of the caliper (longitudinal feed) and the upper caliper rotated at a certain angle.

Depending on the modification of the machine, the following alphanumeric indices are added to the basic designation:

"K" - a machine with a closed rear zone;

"С7" ("SKB IS") - a machine tool with a digital indication device (DRO) with the magnetic transducers of linear movements.

RU

RU EN

EN BY

BY